Design & Innovation

Combining over 128 years’ experience and expertise with leading-edge technology, JB Springs can assist in the design, testing, and production of spring and wireform solutions to solve the most difficult of problems.

We can cite a number of notable innovation success stories across a range of industries which have been the result of our dedicated design team working directly with our customers, or on their behalf.

From Prototype to Production with Precision

We offer complete product development support that not only checks and advises on the feasibility of a concept but helps prove the design. By utilising the very latest technologies and tools we can create working prototypes that aid in the testing and development of the product. This can then reduce the cost and time required to take the spring to production.

Our continued investment in the latest machinery and technologies continually enhances, refines, and streamlines our design and manufacturing processes; benefiting both ourselves and our customers.

From Prototype to Production with Precision

We offer complete product development support that not only checks and advises on the feasibility of a concept but helps prove the design. By utilising the very latest technologies and tools we can create working prototypes that aid in the testing and development of the product. This can then reduce the cost and time required to take the spring to production.

Our continued investment in the latest machinery and technologies continually enhances, refines, and streamlines our design and manufacturing processes; benefiting both ourselves and our customers.

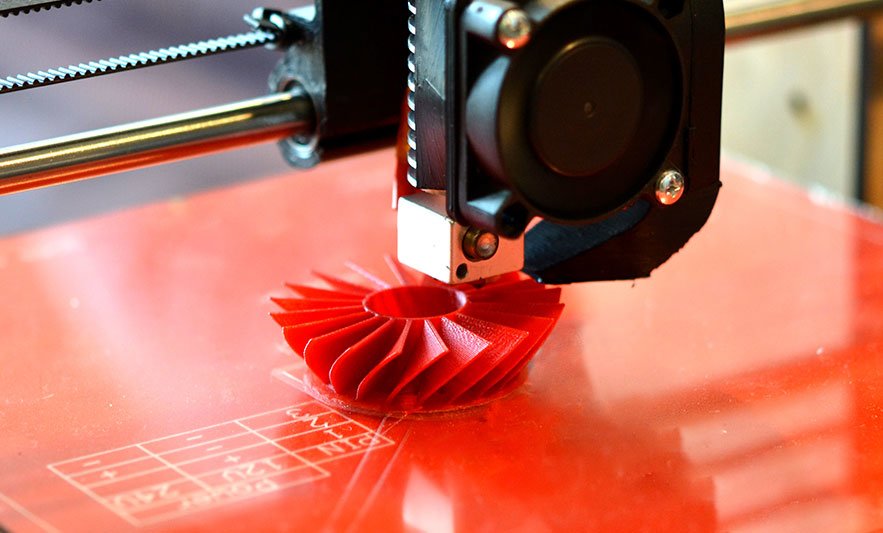

FDM Production Grade 3D Printing

Fused Deposition Modeling (FDM) technology uses production-grade thermoplastics to build strong, durable and dimensionally stable parts with the highest accuracy and repeatability of any current 3D printing technology.

As a result, complex geometries and cavities that would otherwise be problematic become practical with FDM 3D printing technology.

Manufacturing Capability

From our 40,000 square feet purpose-built production facility we have the capacity to manufacture millions of spring and wireform products and parts ranging from 0.30mm – 27.00mm.

Whether our customers require production runs of millions or one-offs, every order is given the same attention to detail, quality and inspection.

We have an extensive stock of raw materials in all sizes and specifications, including exotic alloys, which enables us to rapidly respond to breakdowns, and stock losses. For many of our customers we also stock finished parts.

Manufacturing Capability

From our 40,000 square feet purpose-built production facility we have the capacity to manufacture millions of spring and wireform products and parts ranging from 0.30mm – 27.00mm.

Whether our customers require production runs of millions or one-offs, every order is given the same attention to detail, quality and inspection.

We have an extensive stock of raw materials in all sizes and specifications, including exotic alloys, which enables us to rapidly respond to breakdowns, and stock losses. For many of our customers we also stock finished parts.

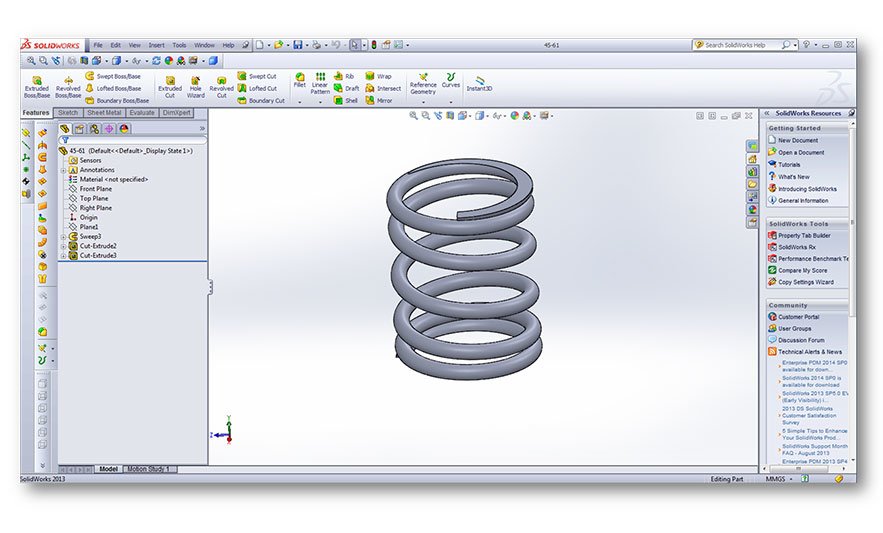

Computer Aided Design (CAD)

We use a range of CAD software and tools during the design and development stage which include:

- CAD Spring Design

- Fatigue Life Prediction

- Spring Design Optimisation

- 3D Design Modelling

- Metallurgical Analysis

- Lifecycle Testing

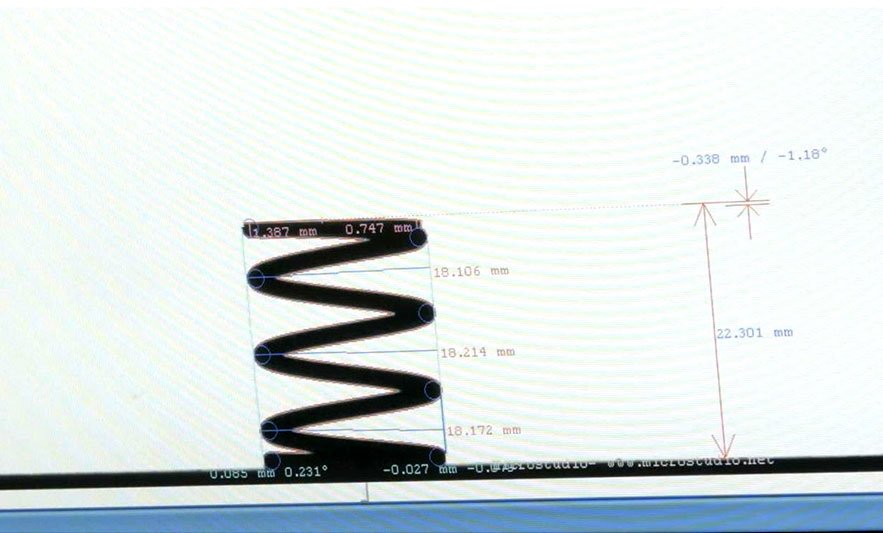

Quality & Inspection

Manufacturing Quality & Value For Life

JB Springs has established an enviable reputation for quality in the manufacture of safety critical spring and wireform parts and components. Our ability to maintain these high standards whilst meeting delivery deadlines is paramount in our service to customers.

Our emphasis on quality is evident throughout the factory and in our ISO 9001:2015 accreditation, though this is seen only as the starting point from which to build.

Each machine is routinely checked to ensure the consistent high quality of our products, while springs can be inspected to BS 1726-Grade 1 standards or customer specified requirements.

The inspection department boasts some of the very latest equipment, including an optical measuring machine produced and installed to our own bespoke design. This enables dimensions including squareness and parallelism to be measured to minute detail.

Quality & Inspection

Manufacturing Quality & Value For Life

JB Springs has established an enviable reputation for quality in the manufacture of safety critical spring and wireform parts and components. Our ability to maintain these high standards whilst meeting delivery deadlines is paramount in our service to customers.

Our emphasis on quality is evident throughout the factory and in our ISO 9001:2015 accreditation, though this is seen only as the starting point from which to build.

Each machine is routinely checked to ensure the consistent high quality of our products, while springs can be inspected to BS 1726-Grade 1 standards or customer specified requirements.

The inspection department boasts some of the very latest equipment, including an optical measuring machine produced and installed to our own bespoke design. This enables dimensions including squareness and parallelism to be measured to minute detail.

Testing

Utilising high quality, state-of-the-art spring testing equipment and machinery we are able to perform a wide range of tests to accurately validate the spring design.

MORE INNOVATION SUCCESS STORIES

Contact Us

Complete and submit the form below providing as much detail as you can about your spring or project and we’ll get back to you as soon as we can.

Follow Us