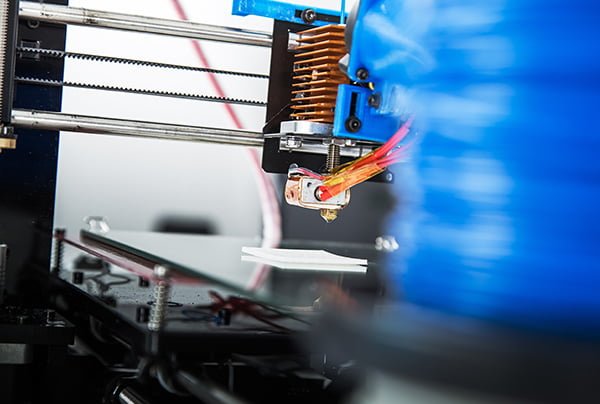

How 3D printing is changing the manufacturing landscape

Many industry experts believe 3D printing, also known as additive manufacturing, is heralding the dawn of the 4th industrial revolution.

Although 3D printing was developed during the 1980s, its evolution and adoption, particularly over the last five years, has gathered pace. The Sculpteo ‘State of 3D printing’ study found that 55 percent of industry professionals surveyed predict that they will be spending more on 3D printing in the next 12 months.

As 3D printing technology continues to mature, growing numbers of manufacturing companies in the UK have adopted 3D printing to boost their service offering to customers.

Sculpteo’s study also revealed that 90 percent of companies using 3D printing consider it as a competitive advantage in their strategy. Other deployments of the manufacturing tool have been used across areas such as healthcare, the automotive industry and more.

There are benefits and there are also challenges to the adoption of additive manufacturing, but with the current state of 3D printing and the increasing demand for unique products and designs, demand for the technology does not seem to be slowing any time soon.

JB Springs has utilised Fused Deposition Modeling (FDM) 3D printing technology as part of our design and innovation service for a number of years now; complementing other leading edge technologies, as well as more traditional manufacturing processes.

Using production-grade thermoplastics we can build strong, durable and dimensionally stable parts with complex geometries and cavities with the highest accuracy and repeatability.

For more information on our design, innovation and 3D printing services click here to contact us.

Follow Us