Heat Treatment: Ensuring high spring quality

In this blog post, we look at the use of heat treatment in spring manufacturing to optimise quality.

The quality of any product is directly and heavily impacted by the procedures carried out during its production. There are a range of processes and practices which can be implemented to ensure the highest quality of manufacture is achieved, with heat treatment being one of these.

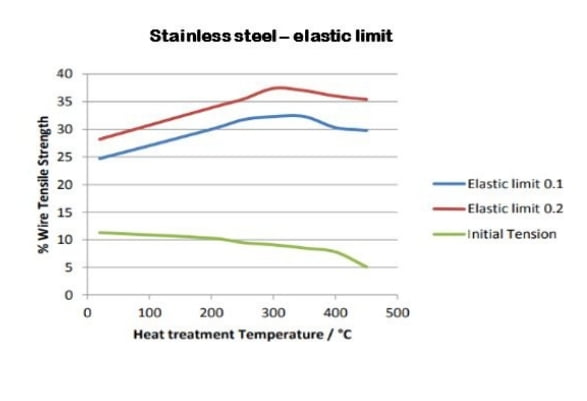

The effect of temperature on initial tension and elastic limit of stainless steel tension springs

What Is Heat Treatment?

Heat treatment of spring materials (as the name would suggest) involves applying a high level of heat (generally between 200 and 350°C) to the wire to increase the elastic limit – but at a temperature that will not reduce the wire’s tensile strength – followed by air-cooling.

One of the main uses of heat treatment is as a stress-relieving process applied to springs to reduce residual tensile stresses on the spring surface, which can develop in wire when it is cold formed. In this context, the process lessens the stresses created during activities including forming, cutting, and machining, amongst others. This offset of residual stresses from plastic deformation intensifies the strength properties of the metal. It also increases the elastic limit, which is key for spring performance.

To phrase it metaphorically, imagine you return home from a hard day at work and have a hot bath to relax. This is similar to springs undergoing heat treatment as a form of stress relief.

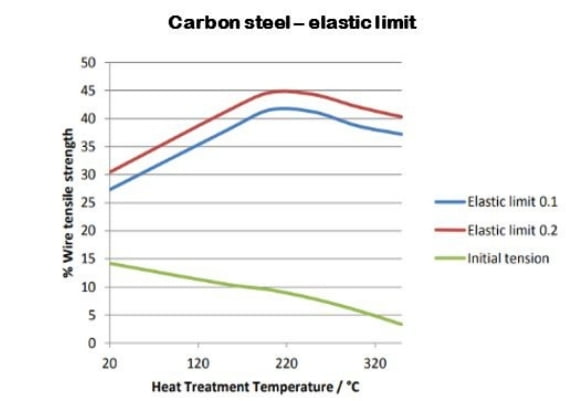

The effect of temperature on initial tension and elastic limit of carbon steel tension springs

As demonstrated in the graphs above, the elastic limit of stainless steel tension springs is substantially lower than that of carbon steel. The temperature is more important than the exposure time to said temperature.

How Heat Treatment Reduces Stress in Springs

If spring materials aren’t heat treated to relieve stress, the spring is unlikely to perform optimally and it is possible the spring may crack during use. Unlike other manufacturing processes, this process doesn’t affect the structure of the vast majority of materials (except exotic alloys).

Heat treatment leaves metals in a suitable condition for further manufacturing processes – increasing the metal strength and elastic limit. This allows for better forming and hardening of the material with less risk of severe cracking or distortion. E.g. if silicon chrome springs aren’t heat treated after coiling, the springs are at greater risk of cracking.

Additionally, the process stabilises spring dimensions. This reduces the risk of deviation from the original outside diameter; this can occur through regular use over a significant period of time. However, during the spring’s manufacture, consider that this application of heat can alter the original outside diameter, spring rate, initial tension and elastic limit.

Post Heat Treatment Stress Relief

Following stress-relieving heat treatment, materials should slowly cool over a couple of hours. This gradual cooling circumvents tensions that build within as a result of drastic changes in temperature during manufacturing.

In conclusion, heat-treating springs improves the performance, longevity, load stability and therefore overall quality of springs. At JB Springs, we apply heat treatment to the springs we produce using inline conveyor ovens. Unlike batch ovens, our conveyor ovens ensure each part receives equal heat coverage and reduces variation in quality.

To discover more about spring manufacturing best practices, browse our other blogs and webpages. Discover others in this series of ‘Ensuring high spring quality through best manufacturing practices’:

Ensuring High Spring Quality Through Best Manufacturing Practices: Shot Peening

Ensuring High Spring Quality Through Best Manufacturing Practices: Prestressing

Alternatively, for a quote or help/advice on a specific topic please visit our Contact Page to submit your enquiry and our team will get back to you.

Follow Us