Prestressing: Ensuring high spring quality

Prestressing is a quality-improving process often implemented during the manufacture of springs – mainly compression springs – to enhance their mechanical properties and improve their fatigue life (life cycle).

The process involves compression by loading a spring past its elastic limit until it reaches a solid position or a predetermined length (the latter is less common) and plastic deformation occurs. This results in a number of enhancements to the spring including:

- Increased elastic deformation

- Increased load capability

- Improved relaxation performance

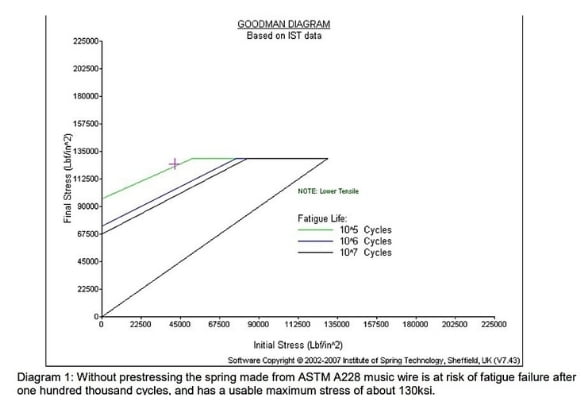

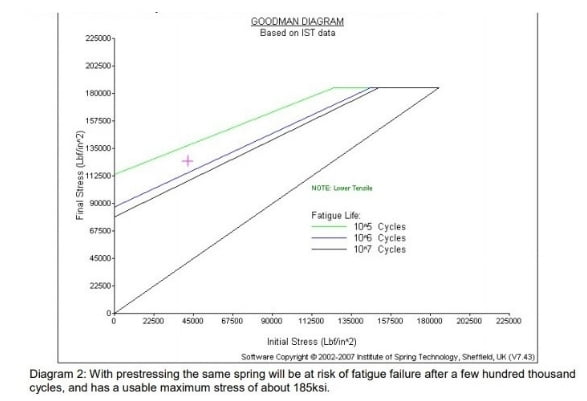

- Improved fatigue life (see the Goodman Diagram below)

These benefits occur as the torsional elastic limit and load capability increase. Also, residual torsional stresses form on the spring’s surface. This enables the spring to perform under higher levels of stress and extending the fatigue life. Essentially, after undergoing prestressing, the spring settles at a height at which it can happily operate.

Something to take into account when prestressing a spring, is that it will likely result in the spring shortening. This is due to the plastic deformation induced through the twisting of the spring. Therefore, the desired dimensions of the final spring product must be considered and calculated to avoid loss of length. Scragging and plug-testing are common terms that are also often used in describing the process of prestressing a spring.

To put it in metaphorical terms, the process of prestressing a spring is similar to if you stretch your muscles to ‘warm-up’ before engaging in exercise. Prestressing better prepares the spring for loads by improving its fatigue resistance, and ability to withstand stress.

Find out more

To find out more about prestressing, visit Spring Expert Mark Hayes’ article on the subject. For best spring manufacturing practices and more information about spring production and performance, have a read of our other blog posts including others in this series such as:

Ensuring High Spring Quality Through Best Manufacturing Practices: Shot Peening

Ensuring High Spring Quality Through Best Manufacturing Practices: Heat Treatment

Alternatively, to request a quote or enquire about how JB Springs can produce quality compression springs, tension springs and torsion springs for lean spring solutions, simply fill out the form on our Contact Page or email us at sales@jbsprings.co.uk and we will duly get back to you.

Follow Us